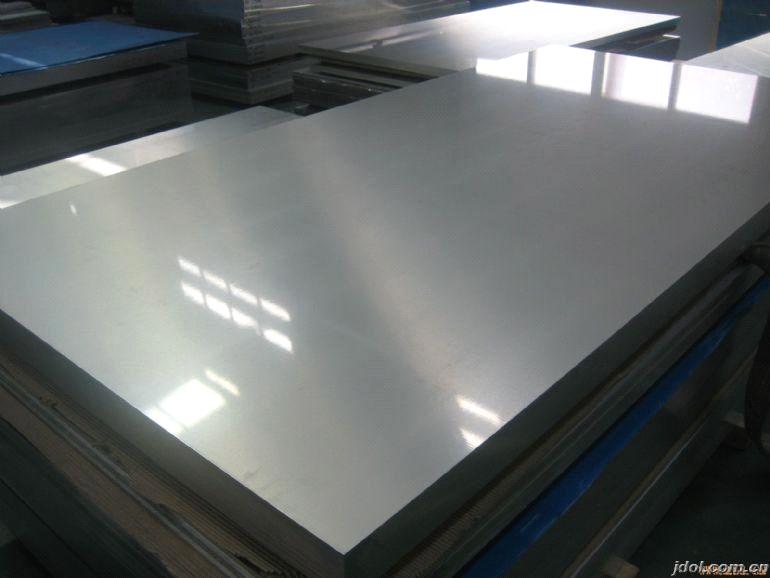

Austenite 321 Stainless Steel |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel 321(UNS S32100)

General Properties While Alloys 321 and 347 continue to be employed for prolonged service in the 800 to 1500 Fahrenheit degree (427 to 816 centigrade degree) temperature range, Alloy 304L has supplanted these stabilized grades for applications involving only welding or short time heating. Alloys 321 and 347 stainless steels are also advantageous for high temperature service because of their good mechanical properties. Alloys 321 and 347 stainless steels offer higher creep and stress rupture properties than Alloy 304 and, particularly, Alloy 304L, which might also be considered for exposures where sensitization and intergranular corrosion are concerns. This results in higher elevated temperature allowable stresses for these stabilized alloys for ASME Boiler and Pressure Vessel Code applications. The 321 and 347 alloys have maximum use temperatures of 1500 Fahrenheit degree (816 centigrade) for code applications like Alloy 304, whereas Alloy 304L is limited to 800 Fahrenheit degree (426 centigtade). High carbon versions of both alloys are available. These grades have UNS designations S32109 and S34709. Forms of 321 stainless steel: Chemical Composition

Shanghai Yikai Metal Products Co., Ltd www.yikaisteel.com Steel supplier in Shanghai, China Skype:jimmyni258 Last product:Austenite 316L Stainless Steel Next product:Austenite 347/347H |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||