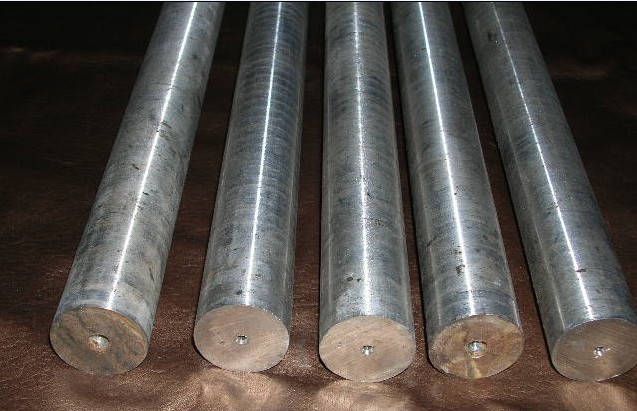

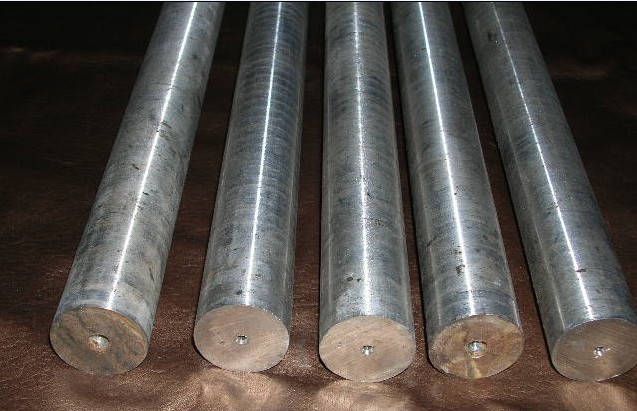

Incoloy 800 Round Bar

Material

Incoloy 800H,800HT, 825, 925, 901 alloy

Standard

ASTM, ASME, BS, DIN, EN, GB

Manufacturing method

Hot-forging, Hot Rolled, Cold Drawn, Bright Finish

and Black finished

Diameter

1-300mm

Length(m)

Random length 3-6m or as customers' requirement.

Applications is Incoloy 800

Ethylene furnace quench boilers

Hydrocarbon cracking

Valves, fittings and other components exposed to corrosive attack from 1100-1800�� F

Industrial furnaces

Heat-treating equipment

Chemical and petrochemical processing

Super-heater and re-heaters in power plants

Pressure vessels

Heat exchangers

Alloys 800/800H are used in a variety of applications involving exposure to corrosive environments and high temperatures such as heat treating equipment, chemical and petrochemical processing, nuclear power plants and the paper pulp industry. Heat-treating equipment such as baskets, trays, and fixtures employ Incoloy 800H/HT. Chemical and petrochemical processing industries use the alloys for heat exchangers and other piping systems in nitric acid media especially where resistance to chloride stress-corrosion cracking is required. Power plants use them for super-heater and re-heater tubing.

Delivery condition

Hot Forging/ Hot-rolled+Annealing/Normalizing/ Tempering/ Quenching

and Tempering/ Solution/ Aging/ Slow Cooling

Tolerance

+/-0.2mm

Surface

Bright Finish, Black Finish, Grinding Finish, Roughing Finish.

Certificate

ISO9001m, ROHS, MTC

or do a test according to clients' requirements.

Packing

Bundles, Wooden cases, pallets, nylon bags

or according to the customers' requirements

Last product:hastelloy c276 wire

Next product:410 Stainless Steel

|