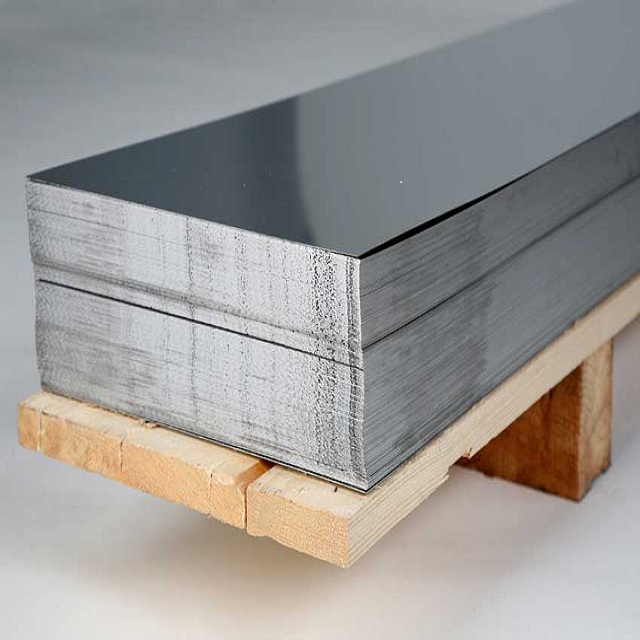

Incoloy 800 H/HT |

Incoloy 800, 800H, and 800HT are nickel-iron-chromium alloys with good strength and excellent resistance to oxidation and carburization in high-temperature exposure. These nickel steel alloys are identical except for the higher level of carbon in alloy 800H, and the addition of up to 1.20 percent aluminum and titanium in alloy 800HT. Incoloy 800 was the first of these alloys and it was slightly modified into Incoloy 800H. This modification was to control carbon (.05-.10%) and grain size to optimize stress rupture properties. Incoloy 800HT has further modifications to the combined titanium and aluminum levels (.85-1.20%) to ensure optimum high temperature properties.The nickel alloy is dual certified (800H/HT) and combines the properties of both forms. Incoloy 800H/HT alloy was intended for high temperature structural applications. The nickel content makes the alloys highly resistant to both chloride stress-corrosion cracking and to embrittlement from precipitation of sigma phase. The general corrosion resistance is excellent. In the solution annealed condition, alloys 800H and 800HT have superior creep and stress rupture properties. Today, most suppliers, including Mega Mex, only carry the dual certified 800H/HT alloy. What are the characteristics of Incoloy 800/800H/800HT? High temperature strength High creep rupture strength Resistant to oxidation and carburization in high temperature environments Good corrosion resistance in many acidic environments Good resistance to many sulfur-containing atmospheres In what applications is Incoloy 800H/HT used? Ethylene furnace quench boilers Hydrocarbon cracking Valves, fittings and other components exposed to corrosive attack from 1100-1800�� F Industrial furnaces Heat-treating equipment Chemical and petrochemical processing Super-heater and re-heaters in power plants Pressure vessels Heat exchangers Incoloy 800 H/HT are used in a variety of applications involving exposure to corrosive environments and high temperatures such as heat treating equipment, chemical and petrochemical processing, nuclear power plants and the paper pulp industry. Heat-treating equipment such as baskets, trays, and fixtures employ Incoloy 800H/HT. Chemical and petrochemical processing industries use the alloys for heat exchangers and other piping systems in nitric acid media especially where resistance to chloride stress-corrosion cracking is required. Power plants use them for super-heater and re-heater tubing. Last product:430 stainless steel bar Next product:Monel K500 |